Zero-gravity Manufacturing: the New Industrial Revolution

In the realm of manufacturing, the concept of zero-gravity is revolutionizing the way products are designed and produced. This cutting-edge technology, previously confined to the realm of science fiction, is now becoming a reality in various industries, from aerospace to healthcare. By harnessing the power of microgravity environments, zero-gravity manufacturing offers a host of benefits that could potentially transform the industrial landscape as we know it.

The Promise of Zero-Gravity Manufacturing

Zero-gravity manufacturing involves the production of goods and materials in a space-like environment where the effects of gravity are minimized or eliminated. This unique setting allows for the creation of products with increased precision, efficiency, and quality. By removing the constraints imposed by gravity, manufacturers can explore new design possibilities and overcome traditional manufacturing limitations.

Enhanced Material Properties

One of the key advantages of zero-gravity manufacturing is its ability to enhance the properties of materials. In a microgravity environment, substances behave differently than they would on Earth, leading to unique characteristics and properties. For example, the formation of alloys and composites can be more uniform and controlled in zero gravity, resulting in stronger and more durable materials. This opens up possibilities for the development of advanced materials that are lighter, stronger, and more resilient than ever before.

Innovative Design Possibilities

Zero-gravity manufacturing also enables designers to push the boundaries of creativity and innovation. Without the constraints of gravity, products can be designed in ways that would be impossible in a traditional manufacturing setting. Complex geometries, intricate structures, and novel configurations can be realized with greater ease and precision. This opens up a world of possibilities for creating products that are not only functional and efficient but also aesthetically pleasing and visually striking.

Applications in Aerospace and Beyond

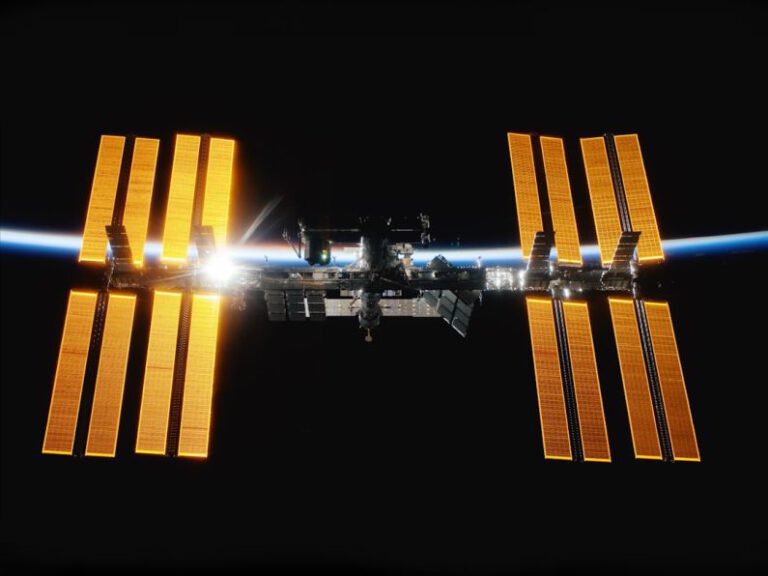

The aerospace industry is one of the primary beneficiaries of zero-gravity manufacturing technology. In space, where gravity is negligible, components can be manufactured with extreme precision and accuracy, leading to lighter and more efficient spacecraft. From satellites to rovers, the applications of zero-gravity manufacturing in the aerospace sector are vast and promising.

Moreover, zero-gravity manufacturing has the potential to revolutionize other industries as well. In healthcare, for instance, the production of medical devices and implants could benefit greatly from the unique properties of materials manufactured in space. Similarly, the automotive and electronics industries stand to gain from the enhanced performance and durability of products created in a zero-gravity environment.

Challenges and Opportunities

While zero-gravity manufacturing holds immense promise, it is not without its challenges. The cost of launching and operating manufacturing facilities in space is a significant barrier for many companies. Additionally, the logistics of transporting raw materials and finished products to and from space add complexity to the manufacturing process. However, as technology advances and space exploration becomes more accessible, these challenges are gradually being overcome.

The Road Ahead: Zero-Gravity Manufacturing in the Future

As we look to the future, the possibilities of zero-gravity manufacturing are truly exciting. With ongoing advancements in space technology and a growing interest in commercial space exploration, the prospect of establishing permanent manufacturing facilities in space is becoming increasingly feasible. Companies and researchers around the world are actively exploring the potential of zero-gravity manufacturing to revolutionize industries and drive innovation.

In conclusion, zero-gravity manufacturing represents a new frontier in industrial production, offering unparalleled opportunities for creativity, efficiency, and quality. By harnessing the unique properties of microgravity environments, manufacturers can unlock a world of possibilities and push the boundaries of what is possible. As we continue to explore the potential of zero-gravity manufacturing, we are on the cusp of a new industrial revolution that has the power to transform the way we design, produce, and innovate.